Register

Flare and Pilot Light Monitoring Solutions

Insight

•

Updated May 5, 2022

Options for effective flare pilot light monitoring: thermocouples and beyond

Berkleigh Armistead

Darcy Partners

Sustainability

Flaring

Introduction

In oil and gas operations, routine flaring is becoming less common as companies adopt zero routine flaring pledges and natural gas prices support prioritizing sale of associated gas. Disruptions, however, still occur which requires gas to be sent to flare. Darcy has seen a recent uptick in the number of inquiries into flare and pilot light monitoring technologies, so we put together an overview of flare monitoring solutions.

Pilot Light Status

There are a few core technologies that are traditionally used to monitor pilot light status on flare stacks; some of these are typically used for industrial and gas plant flares as opposed to smaller pad level or production facility flares, but use case crossover is possible- especially if regulatory bodies require more stringent pilot light monitoring or impose stiffer penalties for unlit flares.

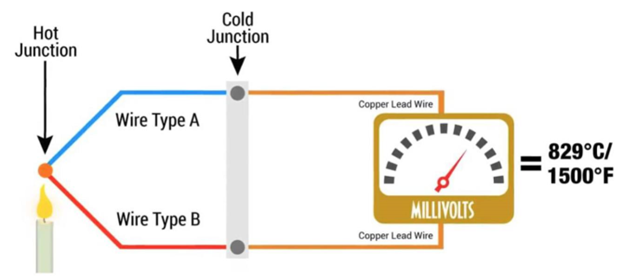

Thermocouples

Thermocouples are the most widely used method of pilot light monitoring. A thermocouple is simply a temperature system that consists of two dissimilar metals joined together that when heated or cooled creates a voltage that can be tied back to temperature. [2] Operators with SCADA systems can tie the thermocouple temperature data into their SCADA system and program an alert for a low temperature threshold that might indicate a pilot light is out. This monitoring method, although simple, is not 100% reliable due to risk of false positives and the fact that these thermocouples are largely considered a disposable item that needs to be replaced frequently. A second method of monitoring can be layered on top of the basic thermocouple method to add additional data points.

Figure 1: Thermocouple Schematic [2]

Figure 1: Thermocouple Schematic [2]

Optical and Thermal Camera Monitoring

A UV, IR, or thermal camera lens is pointed directly at the flare pilot to detect any ultraviolet or infrared light from the pilot light flame or thermal energy. Optical methods can be obscured by weather conditions. [2] In conjunction with thermocouple data, using an optical or thermal camera can add two layers of monitoring to a system. Visual camera systems, like one provided be Andium, can also be used for tracking excessive flaring, detecting black smoke or pilot light outages.

Figure 2: Thermal Flare Monitoring Schematic [3]

Figure 2: Thermal Flare Monitoring Schematic [3]

Acoustic Systems

Acoustic systems are designed to monitor a specific sound signature of a burning pilot light. This is not a widely employed solution but is an option for additional visibility if needed. [1] Vibrational sensors, such as those provided by Sensorfield, are also available to add color to flare stack operational status by confirming gas flow to the flare stack. .

Figure 3: Sensorfield Vibrational Sensor on Flare Elbow

Figure 3: Sensorfield Vibrational Sensor on Flare Elbow

Framework

For these technologies to alert operators to unlit pilots effectively, they need to tie into SCADA systems or have other communication capabilities. For Darcy members, this framework provides some technology solutions for when SCADA is or isn’t available and an overview of the technology experience.

Sources:

[1] https://www.argoflares.com/research/flame-monitoring/

[2] https://www.omega.com/en-us/resources/thermocouple-hub

[3] https://movitherm.com/solutions/remote-monitoring/flareview

Related Content

Emissions Data Management Solutions - Technology Landscape

Sustainability

Methane Emissions

Event Recording - Integrating Emissions Data for Compliance and Operational Action

Sustainability

Methane Emissions

Conduit Power – Introduction Deck

Sustainability

Power & Efficiency

Conduit Power – Data Center Executive Summary (2025)

Sustainability

Power & Efficiency