Register

Upcoming Forum: Hydrogen production through methane pyrolysis

Insight

•

Updated April 14, 2021

In February 2021, C-Zero released the news that they secured $11.5 Million in a Series A funding round co-led by Breakthrough Energy Ventures and Eni Next to produce Hydrogen from Natural Gas. In concordance with our Energy Transition program, we will have Monolith presenting in our forum next week.

Mora Fernández Jurado

Darcy Partners

Energy Transition

Hydrogen

At the beginning of 2021, C-Zero released the news that they secured $11.5 Million in a Series A funding round co-led by Breakthrough Energy Ventures and Eni Next to produce Hydrogen from Natural Gas. This piece of information fit directly with Darcy's Energy Transition Program for next week in which we will be introducing Monolith Materials. Just like C-Zero, Monolith Material has a different hydrogen production system via ”Methane pyrolysis”.

In the last weeks we have been discussing green, gray, and blue hydrogen; their environmental impact, efficiency, and costs. However, as you all may know, there are several colors of hydrogen according to the technology used, energy source and final product, and since it is very difficult to address the differences of all hydrogen types, we have limited our previous studies to green, blue, and gray. What happens with turquoise?

Methane Pyrolysis

The type of hydrogen produced using this technology is called “turquoise hydrogen”. Green and blue hydrogen production methods have been dominating the innovator landscape with new companies rising every day. However, methane pyrolysis seems never to be the case and I am curious why.

How is turquoise hydrogen produced?

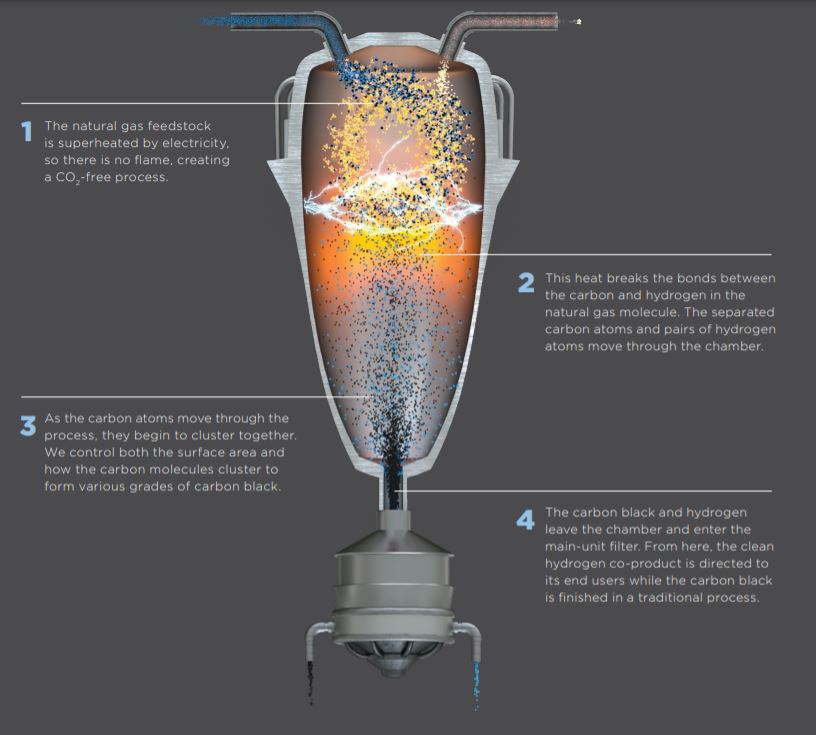

Via methane pyrolysis, using electricity to produce heat, hydrogen and black carbon are produced. The process consists of 5 main steps:

- 1. Natural Gas feedstock is introduced in the reactor.

- 2. The reactor is heated using electricity (when it comes from renewable sources, indirect GHG emissions are reduced)

- 3. The heat breaks the methane molecules (CH4 --> C (s) + 2 H2)

- 4. As the carbon atoms move through the chamber, they begin to cluster together

- 5. Finally, H2 and solid carbon exit the chamber (H2 as a gas and carbon as a solid).

Figure 1. Monolith Process

Figure 1. Monolith Process

GHG Emissions

As you can see, during the process, the only input is methane, and the outputs are carbon and hydrogen. Therefore, there are zero local emissions to this process. Furthermore, if the electricity used for heating comes from renewable sources, this might even be a carbon negative hydrogen production method. In comparison to blue hydrogen, this gives turquoise an advantage.

Efficiency and Economics

Darcy proprietary data suggested that using this type of technology roughly 50-55% of hydrogen is produced vs. SMR systems (steam methane reforming). Additionally, producing hydrogen from methane pyrolysis suggests that the costs will be around $2 per kilogram of hydrogen, whereas blue hydrogen costs should be some 35% less. Initially, this strikes home, and it might sound inefficient and expensive. However, these numbers do not take into account the possible value of sold solid carbon and its multiple uses in the industry.

Monolith has an already active methane pyrolysis facility that sells both hydrogen and carbon. Is it be possible to lower hydrogen production costs by leveraging the price with the sold carbon? Could this tilt the scales towards a zero-emission hydrogen production system? Join us next week to discuss this with Monolith and keep the conversation going!

Please keep in mind that all previous analyses were performed without detailed knowledge of the company numbers and are based on public information

Relevant Links:

Related Content

Downhole Check Valves for CO2 EOR and CCS Applications - Innovator Comparison

Energy Transition

Oil & Gas

Carbon

Completions

Production

AirJoule Overview & Data Center Application

Energy Transition

Sustainability

New Energies

Power & Efficiency

Event Recording - Real Flue Gases, Lower Cost Pilots: Meet CCU at the NCCC

Energy Transition

Carbon

Failure Modes of Non-Metallic Pipelines at Connections

Energy Transition

Industrial Decarbonization

Oil & Gas

Completions

H2 & Low Carbon Fuels

Hydrogen

Production